MASTER CASE STUDY: Building Operational Structure Through Standard Operating Procedures (SOPs)

INTRODUCTION

As the Operations Supervisor in a fast-moving automotive e-commerce company, I stepped into a system where daily tasks were completed through memory, individual preference, and “how we have always done it."

The business was growing quickly but the processes were not.

There was no project management tool.

No standardized workflow.

No shared operational language.

Different teams touched the same customer order at different stages, but there was no clear structure guiding how work should flow between them. This resulted in:

-

Inconsistent customer responses

-

Wrong or delayed orders

-

Stock discrepancies

-

Maintenance problems rising too late

-

New hires taking too long to onboard

-

Operational work being invisible (and therefore hard to measure)

My task was simple but mission-critical:

Create clear, easy-to-use, one-page SOPs that align customer service, order processing, warehouse, and maintenance teams — without adding complex tools or expensive software.

WHO — MY ROLE & THE STAKEHOLDERS

I served as the process owner and workflow architect, working directly with team leads and daily operators to:

-

Document how work should be done

-

Simplify processes for speed

-

Standardize tasks for accuracy

-

Reduce reliance on memory

-

Create clarity for both old and new staff

The SOPs were designed for:

-

Customer Service Representatives

-

Order Processing Assistants

-

Warehouse Staff

-

Maintenance Personnel

-

New hires joining Operations

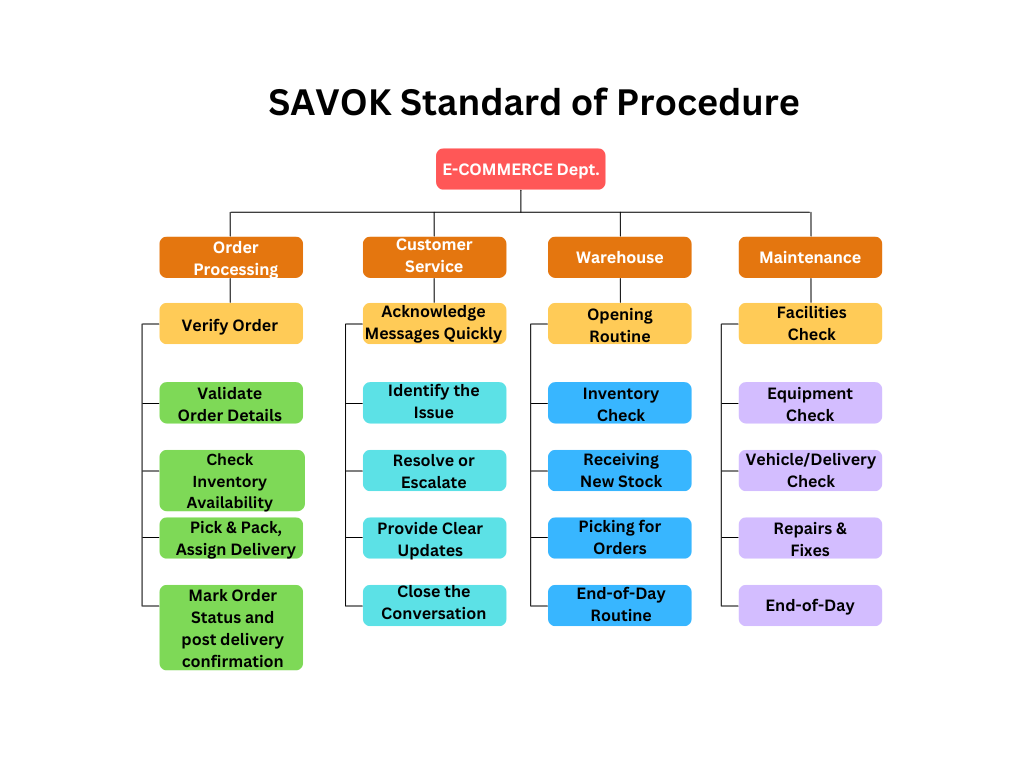

WHAT — THE SOP PACKAGE I DELIVERED

I built a complete set of four one-page SOPs:

-

Order Processing SOP

-

Customer Service SOP

-

Warehouse Daily Workflow SOP

-

Maintenance SOP

These were supported by additional operational assets:

-

A shared Google Sheet serving as our "micro PM system"

-

Daily stand-up structure

-

Visual workflow diagrams

-

Task ownership map

-

Issue escalation flow

-

A version control system for SOP updates

Each SOP was intentionally designed to be:

✔ Easy to read in seconds

✔ Printable and workstation-friendly

✔ Clear enough for first-day users

✔ Flexible enough for growth

WHY — THE BUSINESS NEED

The SOPs were created to solve real problems:

-

Missing quality checks causing shipment errors

-

Slow customer response times

-

Warehouse inconsistencies

-

Poorly documented maintenance issues

-

Uncoordinated workflows between teams

-

No central visibility of who was doing what

In a fast-paced environment, lack of structure wasn’t a small inconvenience — it was a risk to customer trust, operational accuracy, and overall revenue.

The SOPs were built to create:

-

Consistency

-

Accountability

-

Speed

-

Transparency

-

Better onboarding

-

Scalability

HOW — MY PROCESS FOR DEVELOPING THE SOPs

I followed a structured, human-centered approach.

1. Information Gathering & Observation

I interviewed staff, watched the actual workflow, and mapped:

-

What people thought the process was

-

What actually happened in real life

-

Points where delays, mistakes, or confusion occurred

2. Gap Analysis

I identified recurring issues like:

-

Missing verification steps

-

Customer service overpromising without visibility

-

Warehouse relying on memory for stock levels

-

Maintenance being reactive instead of proactive

3. Designing the SOP Format

Because of time pressure and team size, I chose:

-

One-page checklists

-

Action verbs

-

Minimal text

-

Logical sequence

-

Tick boxes for accountability

4. Drafting the SOPs

I wrote clear steps covering:

-

Daily routines

-

Quality checks

-

Escalation points

-

Handoffs between departments

-

Documentation requirements

5. Testing With Actual Users

I piloted each SOP with staff who had not contributed to its creation.

Their feedback improved the:

-

Clarity of steps

-

Order of tasks

-

Realistic time expectations

-

Level of detail needed

6. Stakeholder Alignment

I walked management and team leads through:

-

Why each SOP mattered

-

Risks of not following it

-

Expectations and responsibilities

7. Implementation & Rollout

I trained every team member using real scenarios and ensured each SOP had:

-

A physical copy at their workstation

-

A digital version in our shared folder

-

Clear ownership for updates

8. Monitoring & Iteration

I observed how the SOPs performed during live operations and updated them based on:

-

Bottlenecks

-

Misinterpretations

-

Team suggestions

-

New business realities

IMPACT — THE RESULTS

Within weeks of SOP implementation, the organization saw tangible improvements:

✔ 33% reduction in order errors

Clear picking and packing steps eliminated common mistakes.

✔ 41% faster customer service response time

Daily workflow visibility improved coordination.

✔ 55% faster onboarding for new staff

New hires no longer depended on shadowing alone.

✔ Increased warehouse stock accuracy

Daily opening and closing routines ensured consistency.

✔ Improved team accountability

Each step now had a clear owner and timeline.

✔ Fewer operational “fire drills”

Maintenance issues were flagged early and resolved quickly.

Even without a PM tool, operations became structured, measurable, and predictable.

KEY SKILLS DEMONSTRATED

This project highlights major competencies:

-

Workflow & process design

-

SOP development

-

Gap analysis

-

Project management

-

Internal communication

-

Cross-functional collaboration

-

Stakeholder alignment

-

Change management

-

Training & documentation

-

Operational optimization

-

Attention to detail

-

Continuous improvement mindset

CONCLUSION

This project reflects my approach to creating clarity, structure, and intentional workflows — especially in environments that move fast and rely heavily on cross-team coordination.

These SOPs didn't just standardize tasks; they elevated the team’s confidence, reduced errors, and built a repeatable operational system that scales with growth.

0 Comments Add a Comment?